Tips for Drying Active Pharmaceutical Ingredients 20071103

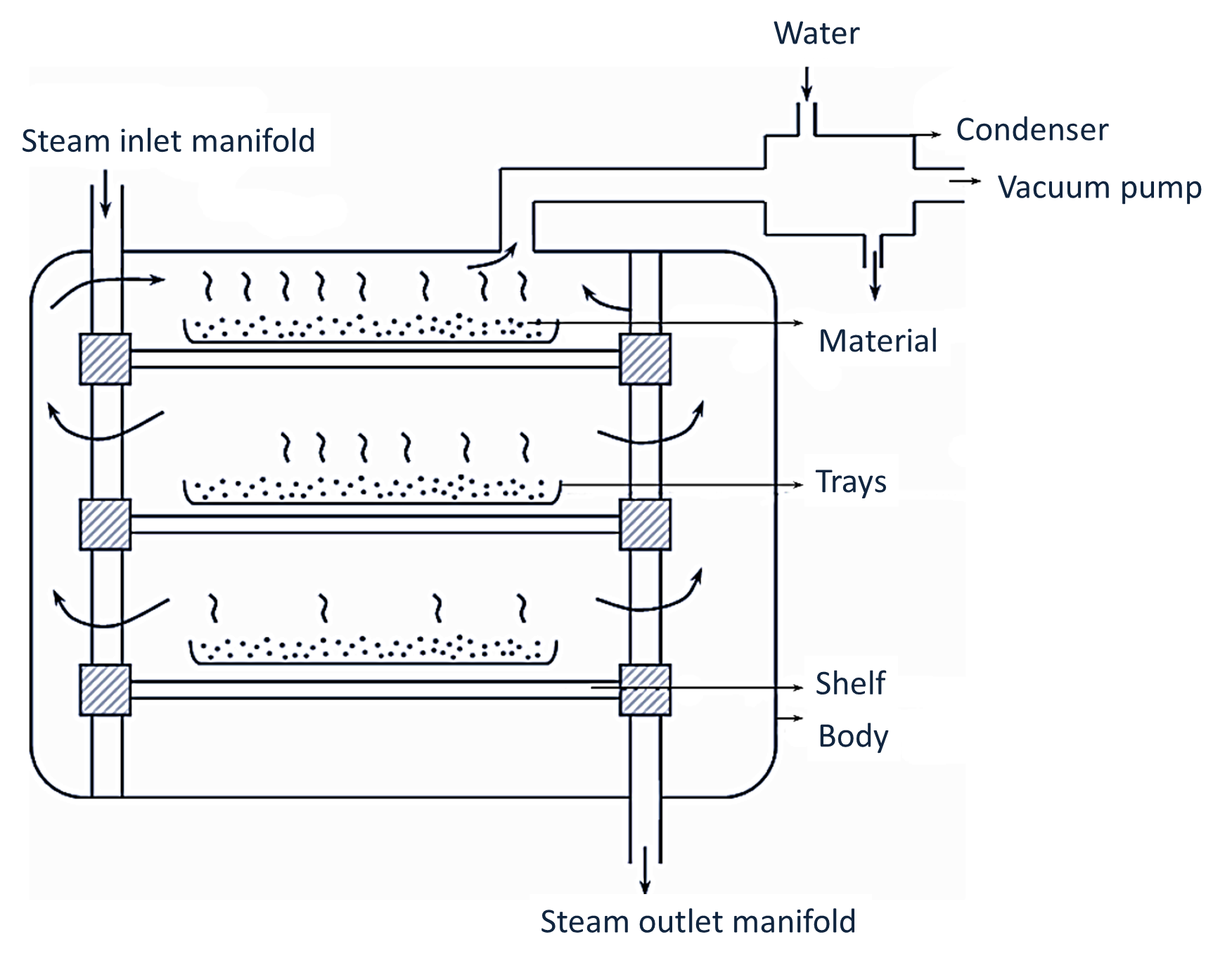

Advantages: Disadvantages: Principle of the vacuum dryer In a vacuum dryer, the material is dried by the application of a vacuum. When the vacuum is created, the pressure is lowered so that water boils at a lower temperature. Hence, water evaporates faster. The heat transfer becomes efficient, i.e., the rate of drying enhances substantially.

Types of Dryers Components, Types, Applications and Advantages

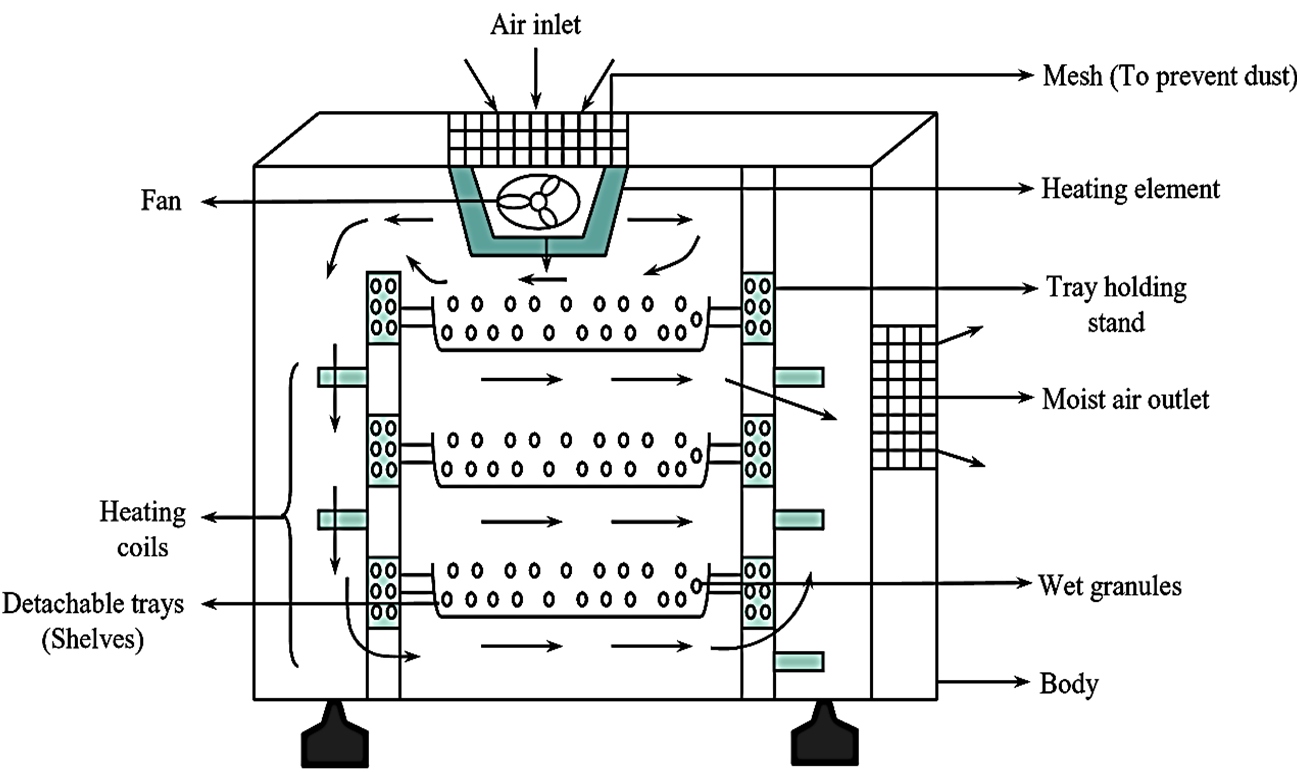

Drying is a straightforward process. The temperature within a drying chamber is raised to the boiling point of a solvent, supplying heat to a moist feedstock until any free or bound liquid within vaporises. Free moisture on the surface evaporates relatively quickly, while bound moisture within the product first must escape the solid microstructure.

Simplified dryers layout drawing. A = Horizontal vacuum rotary drier; B

Tray dryers. The most common dryer for laboratory and small-scale pilot work is the vacuum tray dryer (Figure 2). Heat transfer in this type is largely by conduction or by ra- diation. The trays.

Schematic of the microwave vacuum dryer. metal thermocouples. Most

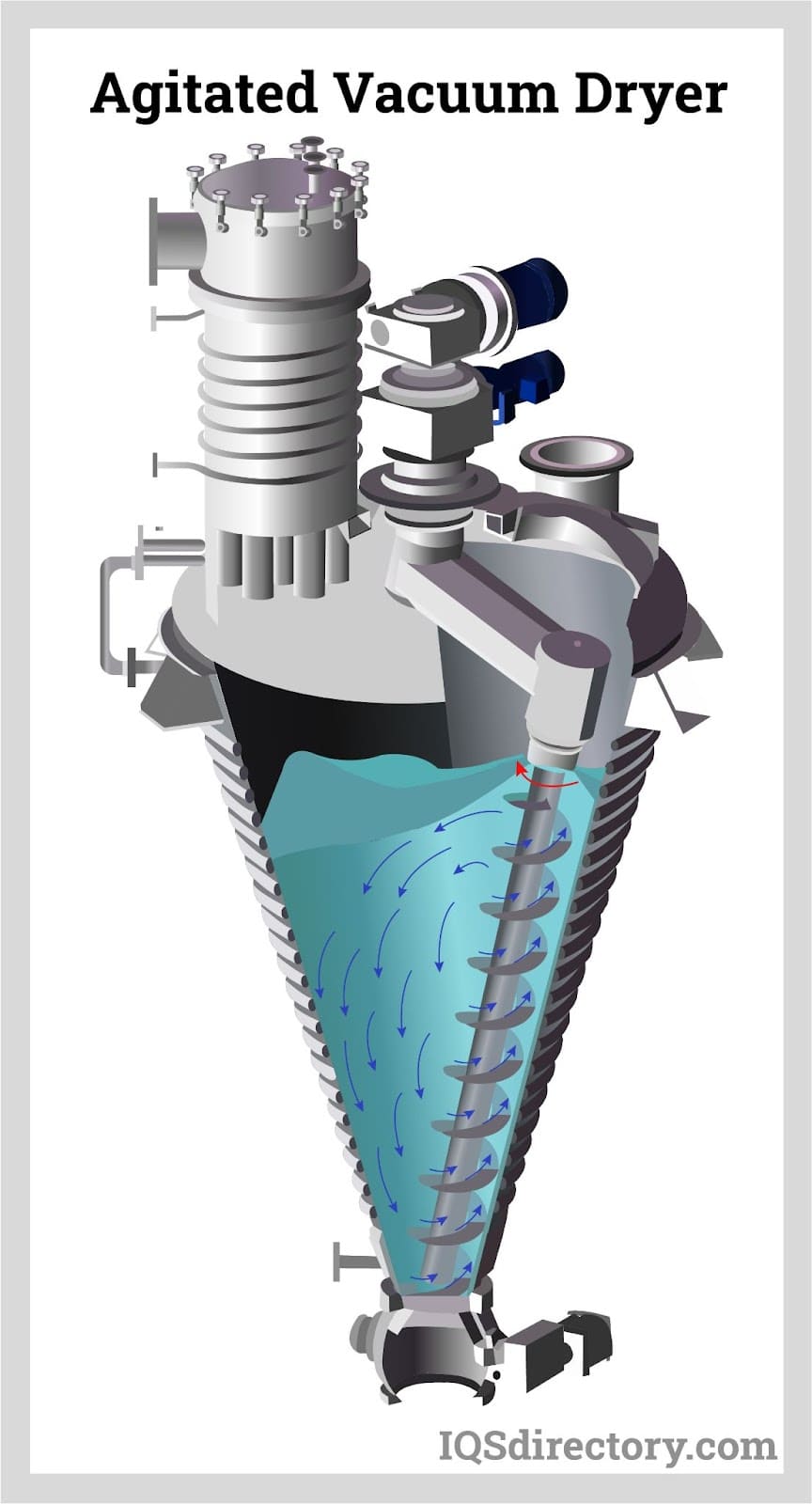

September 22, 2023 by Reshma Kadam Rotary Cone Vacuum Dryer Revolutionizing Drying Technology: The Rotary Cone Vacuum Tray Dryer RCVD is a type of dryers used in chemical, pharmaceutical, and in dyne industry for drying purpose. Today we lean about it in more details.

Scheme of a vacuum dryer of continuous action Download Scientific Diagram

Part 1 Vacuum Drying: basics and application Vacuum drying can be a useful tool for solid products that are heat-sensitive. Here are some guidelines for the selection and use of various types.

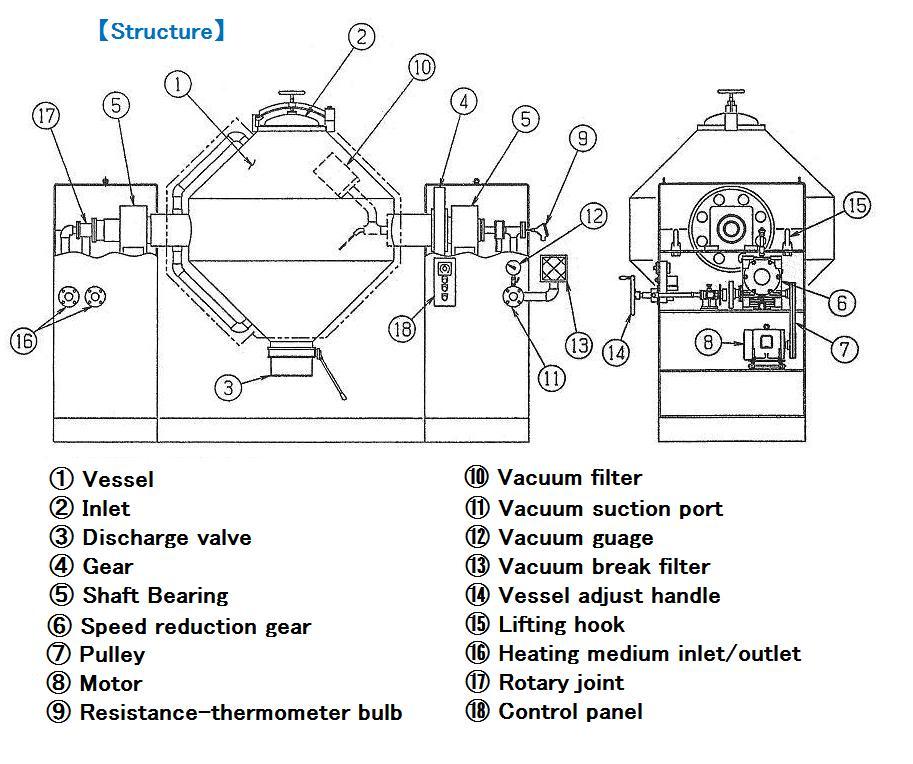

Rotary Vacuum Dryer WDV Rotary Vacuum Dryer Dryers & Coolers

Applications Vacuum dryer can be used to dry heat sensitive hygroscopic and toxic materials. If the feed for drying is a solution, it can be dried using vacuum dryer as the solvent can be recovered by condensation.

Chemistry Archives Page 3 of 4 ElectricalWorkbook

Page 82 Maguire Products, Inc. VBD® - Vacuum Dryer® Pneumatic Diagram Rev. August 31, 2016 - VBD-150. Page 83: Recommended Spare Parts List 11,000 watt 3 phase 575 VAC main cabinet ehsl-02 strobe light, red, magnetic base, 24VDC top deck ehb-2 piezo buzzer, 24VDC front control panel esh-01 interlock handle, red/yellow pistol front control.

Batch Drying With Vacuum Contact Dryers Chemical Engineering Page 1

https://www.facebook.com/groups/258110752186093/filesB.pharm Third semester Pharmaceutical Engineering //Chapter :Drying //Topic: Vacuum dryer Principle, con.

Schematic diagram of microwavevacuum dryer Download Scientific Diagram

Some good practices for the vacuum drying setup include. Run the vacuum hoses downhill from the siphon and vent ports to help drain water from. the lines and decrease the chance of freezing water in the lines. Check and replace the seals on the KF/QF connections often. Over time the seals in.

Vacuum drying process Download Scientific Diagram

The dryer consisted of drying chamber, insulated carefully with rock wool, with an inner dimension of 30 9 30 9 30 cm 3 , heating section, temperature control section, vacuum sec- tion, weighing.

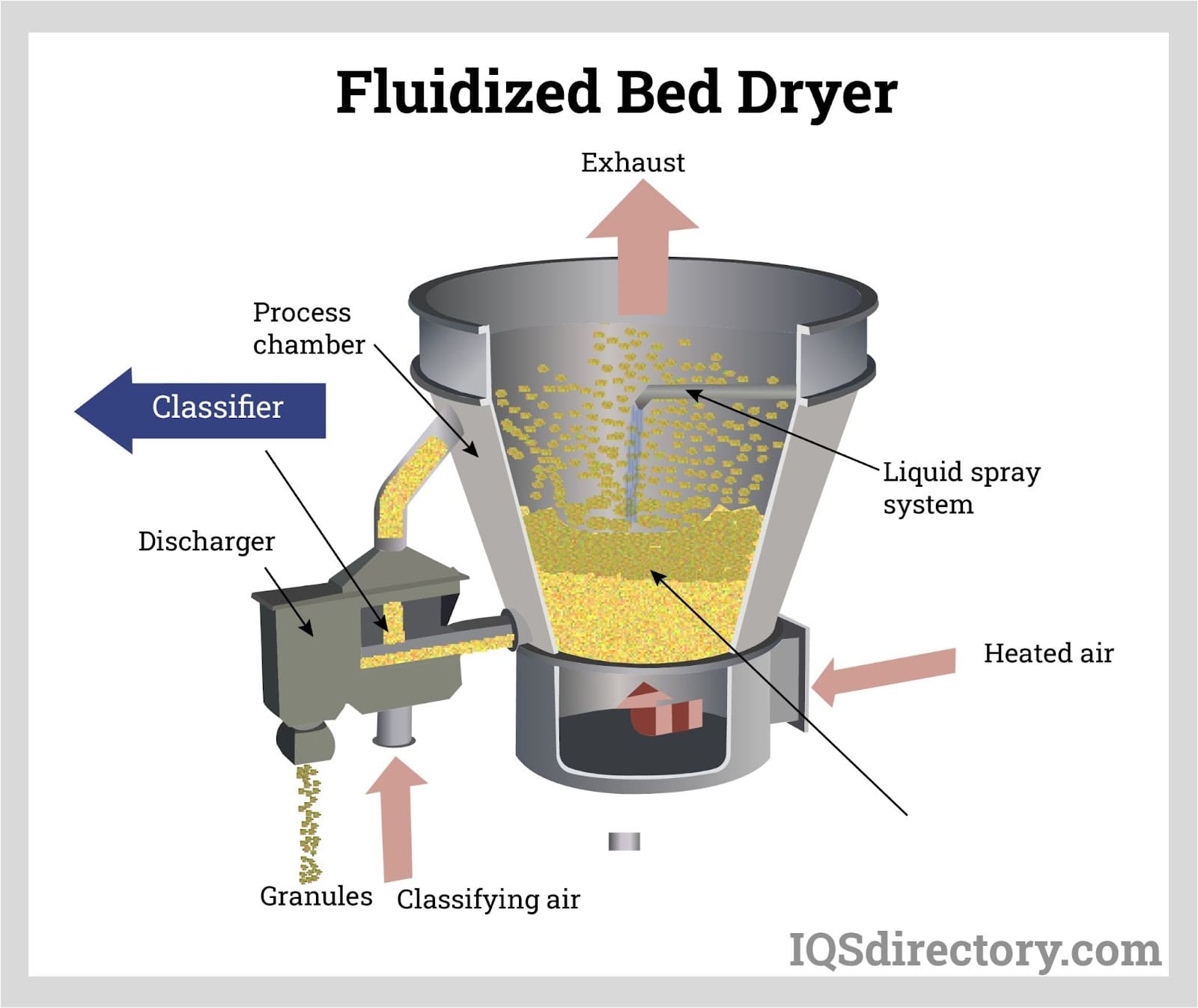

Fluidised bed dryer Vacuum dryer working principle Part4, Unit3

Download scientific diagram | Schematic diagram of the vacuum dryer system. (1) Drying chamber, (2) Drying chamber plate, termed as header plate, (3) Vacuum gauge, (4) Vapour temperature gauge, (5.

Schematic of the highfrequency current / vacuum dryer Download

Here are some essential specifications to consider: Capacity: Determine the desired batch size or throughput you need the Vacuum Tray Dryer to handle. Capacity is often specified in terms of the number of trays or the volume of materials it can accommodate. Temperature Range: Check the temperature range the VTD can achieve.

What is Tray Dryer? Working Principle, Construction, Diagram

Introduction. Rotary vacuum dryers offer clean, simple and effective method of drying wet cake, powder and even slurry. Labor and energy costs are minimal compared to tray dryers and product losses during handling are also negligible. Additionally valuable organic solvents can be conveniently condensed and recovered.

Complete overview of a microwave vacuum dryer Download Scientific Diagram

Vacuum drying is the mass transfer operation in which the moisture present in a substance, usually a wet solid, is removed by means of creating a vacuum. In chemical processing industries like food processing, pharmacology, agriculture, and textiles, drying is an essential unit operation to remove moisture.

Rotary Vacuum Dryer, रोटरी वैक्यूम ड्रायर in Panvel, Navi Mumbai , Geo

#VacuumTrayDryers #VTD #VTDWorking Friends in today's lecture we will discusss about VTD. Principle and Basics of Vacuum tray dryer is explained in full det.

Types of Dryers Components, Types, Applications and Advantages

Vacuum drying is a batch operation performed in an air-tight vessel. Using vacuum pumps, the pressure and humidity within the chamber are reduced. By lowering the atmospheric pressure within the chamber, the materials inside dry more quickly through contact with the indirectly heated walls.